MAIN CATEGORIES OF EPS PRODUCTS

About Iranian West Foam

Why us?

Contact us

Address:

Chenaran Alley Iranian West Foam, Chaharbagh city, Karaj, Alborz Province, Iran

Contact phone:

telefax:

telefax:(+98) 26 443 743 39

telefax:(+98) 26 443 743 40

Email:

Buy Expanded Polystyrene (EPS) at Affordable Prices in Karaj

This material is white and polymeric, serving as an excellent insulator against heat, moisture, and sound. EPS sheets are popular in building for wall and ceiling insulation.

The weight, size, and density of EPS sheets play a crucial role in determining their price, as all applications of this product depend on its dimensions.

When purchasing EPS sheets, it is important to ensure both the material’s composition and its freshness and quality. When polystyrene enters foam production factories for ceilings, it is subjected to high-pressure steam machines, resulting in large blocks as the initial output.

For purchasing EPS sheets for ceilings, packaging, or other applications, several factors should be carefully considered, including compressive and impact resistance, moisture absorption, fire resistance, density, polymerization process, thickness, and dimensions.

In general, the price of EPS sheets depends on multiple factors, the most important of which are:

- Standard size and dimensions of EPS sheets

- EPS density

- Quality of raw materials

- Type of polymerization and curing process

- Required usage area

- Transportation and installation costs

- Raw materials used

- Manufacturing company and brand of EPS sheets

Types of styrofoam and their characteristics

What is EPS?

What is EPS Density?

densities 7,10,12,13,15,16,18,20,25 and 30 kg/m³.

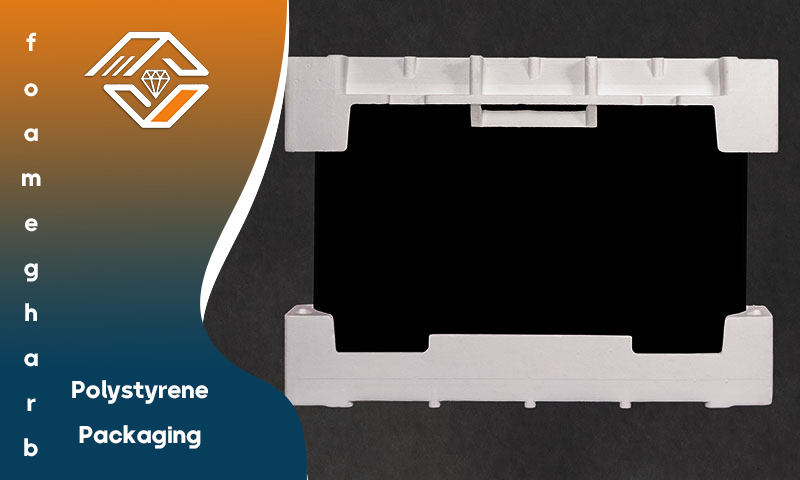

- Packaging EPS density:18 to 20kg/m³

- Construction EPS or ceiling blocks: Determined based on the client’s requirements; most commonly used densities are 7, 10, 15, and 20 kg/m³.

The EPS density number multiplied by 2 gives an approximate weight of the sheet.

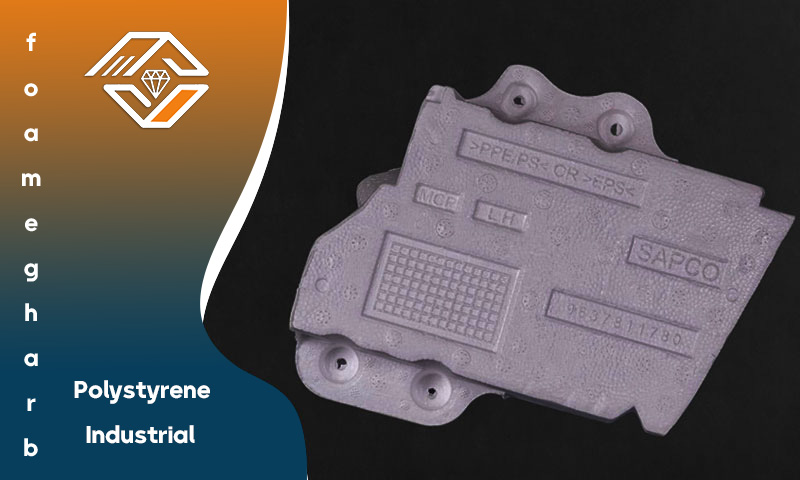

Applications of High-Density EPS

Ceiling EPS (Blocks)

- Standard ceiling EPS dimensions: 2 m length x 25 cm height x 50 cm width

- Standard density: 12 kg/m³

EPS Sheets (Flat EPS)

What is EPS Used For?

The main application of EPS (Expanded Polystyrene) is protection.

EPS is a lightweight, durable, and thermal-insulating material, making it an ideal solution for packaging products of various sizes.

It is also widely used in construction, where EPS sheets or blocks help reduce the overall weight of structures while providing excellent insulation.

EPS Coolers

EPS coolers (foam iceboxes) are one of the most important products made from EPS.

The internal temperature of the cooler rises slowly, making it ideal for exporting broccoli, certain vegetables, temperature-sensitive medicines, and more.

They are also very effective for personal use when combined with dry ice, and are perfect for transporting meat, food, and beverages while keeping them cool.

EPS coolers are considered a type of packaging product, and Iranian West Foam Development Company is one of the largest manufacturers of these in Iran.

These high-density EPS boxes are particularly suitable for transporting temperature-sensitive medicines.

Sellers can order these coolers in any size and any quantity according to their needs.

EPS Production

The production of EPS starts with heating raw materials to convert them into EPS granules.

Depending on the intended application, these granules are injected into molds, where heat, pressure, and air shape them into the desired EPS product.

Next, the formed EPS products are removed from the molds using cold water and air.

Finally, the products are placed into industrial drying units according to their intended use.

EPS Mold Production

EPS molds are created based on technical drawings provided by the client, which include all product details.

A prototype is first made in CATIA software for evaluation. If the prototype matches the product specifications, an aluminum mold is manufactured.

The mold, operated either automatically or manually, produces the final EPS product in the desired quantity.

If software drawings cannot be provided by the client, 2D paper drawings or a physical product sample can be sent to the factory.

The mold-making team prepares the mold based on the product details, produces the prototype, and after client approval, the EPS product is manufactured.

EPS Machines

There are two types of EPS machines:

-

Automatic Press Machine

-

Manual Press Machine

Iranian West Foam has both types, allowing the production of custom EPS products in any quantity.

-

Automatic machines are used for large production volumes, as mold-making costs are higher.

-

Manual press machines are operated by a skilled operator who controls water pressure, material injection, and processing time to produce the final EPS product.

-

Manual presses are typically used for small production runs.

Ordering EPS Across Iran

With over 25 years of experience, Iranian West Foam Development Company enables clients from all over Iran to order any type of EPS product in any quantity.