Iranian West Foam Development Company is an active manufacturer in the field of Expanded Polystyrene (EPS) products in Iran. With more than 25 years of experience, the company has successfully provided a wide range of practical and high-quality services and products to its customers.

Ordering Polystyrene packaging

Place your order for EPS with your desired specifications and receive it in the shortest possible time.

Polystyrene Gharb Iranian Co. produces and supplies EPS blocks in any dimensions and sizes you need, offering the best price and the highest quality.

Contact foamegharb

Factory address:

Chenaran Alley Iranian West Foam, Chaharbagh city, Karaj, Alborz Province, Iran

What Is EPS Packaging?

EPS (Expanded Polystyrene) has many features that have caused a major revolution over the past two decades in various industries, including construction, packaging, automotive manufacturing, agriculture, medical equipment, home appliances, and more. Some of these key features include high resistance to water and moisture penetration, pressure and impact resistance, shock absorption, sound insulation, and thermal insulation.

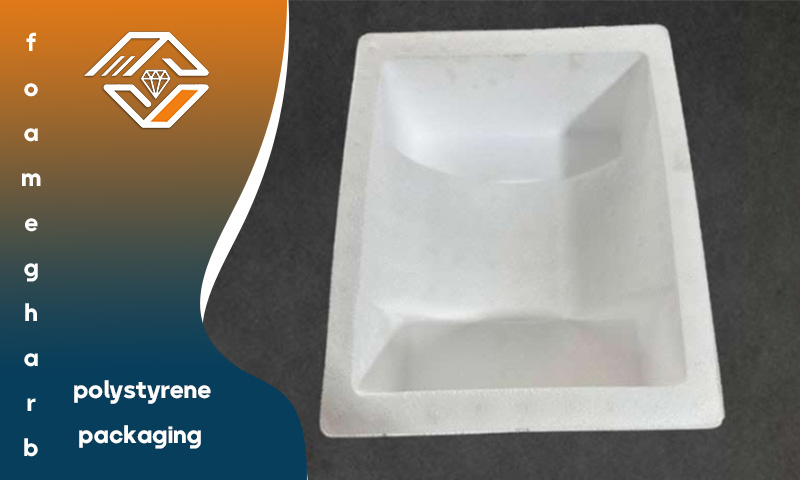

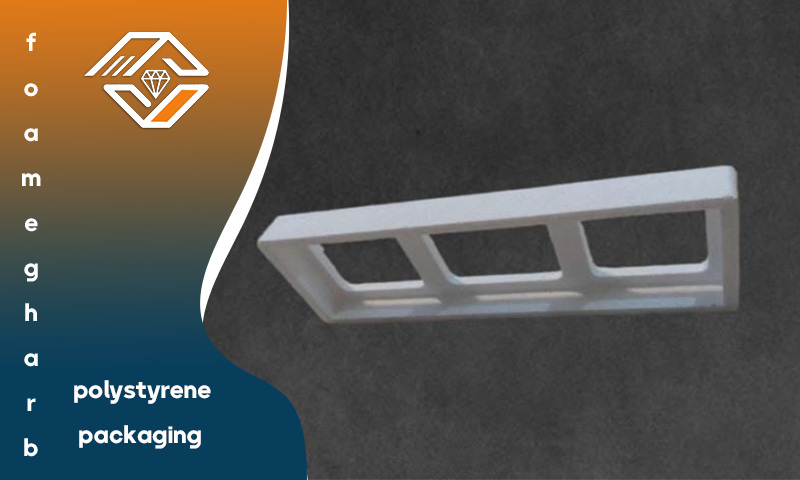

One of the most widely used types of EPS in different industries is EPS packaging, also known as packaging foam. Polystyrene packaging is ideal for protecting sensitive and fragile goods.

Polystyrene packaging is produced and supplied in various forms, and many factories and companies use it for packaging their products.

In the past, product packaging did not receive much attention. However, today companies and brands place great importance on the art of packaging and its design, as it significantly contributes to their market success.

In fact, companies and brands have realized that product packaging visually represents all the effort, quality, and value of the product at first glance in the customer’s mind.

Price of Polystyrene packaging

To determine the price of different types of EPS, several factors must be considered. The most important ones include the brand and manufacturer of the EPS, transportation costs, the required volume or square footage, the type of raw materials and the EPS molding/processing method, physical characteristics such as thickness, width, length, and height, the density of the EPS, currency fluctuations, the design requirements, and any customization needed for Polystyrene packaging.

Therefore, it is not possible to provide a fixed or universal price for EPS packaging.

Purchasing Polystyrene packaging

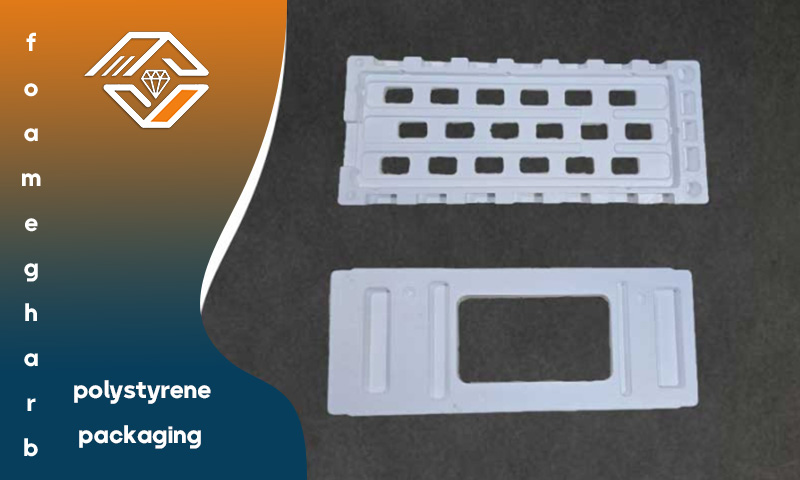

As mentioned earlier, Polystyrene packaging has multiple applications and comes in various forms, such as EPS sheets and fully customized EPS packaging.

Polystyrene packaging is produced in different shapes and volumes using Expanded Polystyrene (EPS). It is one of the best options for protecting delicate and sensitive items against impact and is highly practical for transporting such goods.

It is also widely used for packaging many types of pharmaceuticals and electronic devices. EPS coolers, which are a type of Polystyrene packaging, can keep fresh foods, frozen items, and vegetables at low temperatures. During transportation and handling, these materials remain fully protected without exposure to damage or heat.

Polystyrene packaging in Tehran

If you are in Tehran and need Polystyrene packaging, you can simply contact our specialists or visit the factory in person.

Just provide the dimensions, sizes, and required quantity of the Polystyrene packaging you need, and our experts will process your order.

Wholesale Sale of Polystyrene packaging

Product packaging plays a significant role in overall sales performance. By placing an order for Polystyrene packaging, you can be confident that you will receive the best and most suitable packaging for your manufactured products. We produce fully customized and specialized Polystyrene packaging based entirely on your requirements.

Iranian West Foam Development Company registers wholesale orders for Polystyrene packaging requested by valued customers, both in person and by phone. Your order will be prepared and shipped as quickly as possible. Our company delivers packaging foam to all regions across Iran.

Polystyrene packaging Manufacturing Factory

Today, many factories use Polystyrene packaging to ensure the safe transportation of their manufactured products. As a result, the production of Polystyrene packaging has grown significantly in recent years.

Polystyrene packaging, which is one of the main products of Iranian West Foam Development Company, is produced as an essential material for manufacturers to ensure their products reach consumers without damage.

The Polystyrene packaging manufacturing facility has successfully met the needs of producers by supplying this highly practical and protective material.

Types of Polystyrene packaging

At Iranian West Foam Development Company, our specialty is producing a wide range of polystyrene (EPS) products, including Polystyrene packaging, industrial EPS, construction EPS, and more.

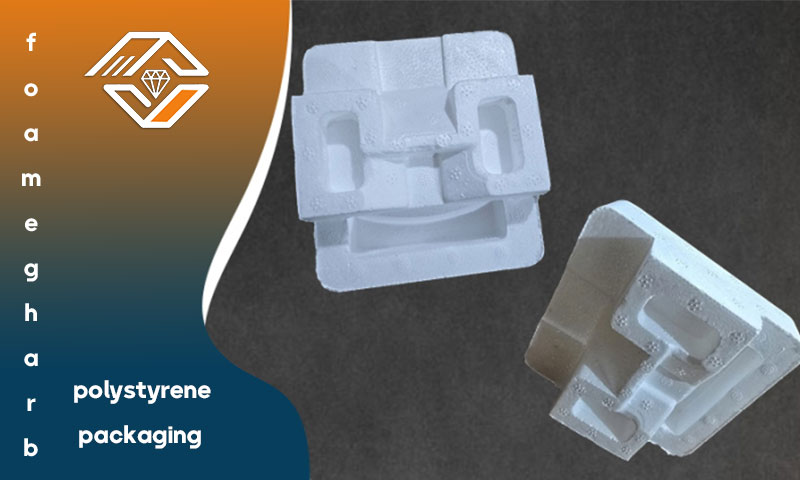

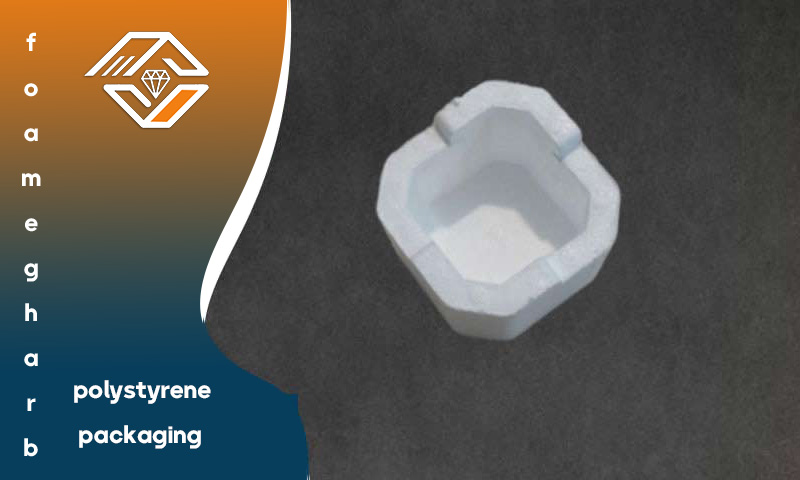

Polystyrene packaging is an essential requirement for various industries such as home appliance manufacturing, automotive parts packaging, kitchenware, pharmaceutical packaging, and many others. Thanks to our company’s advanced capability in custom mold production, we are able to manufacture packaging molds tailored to the exact shape, dimensions, or even 3D/2D design of the final product.

Polystyrene packaging is divided into two main categories:

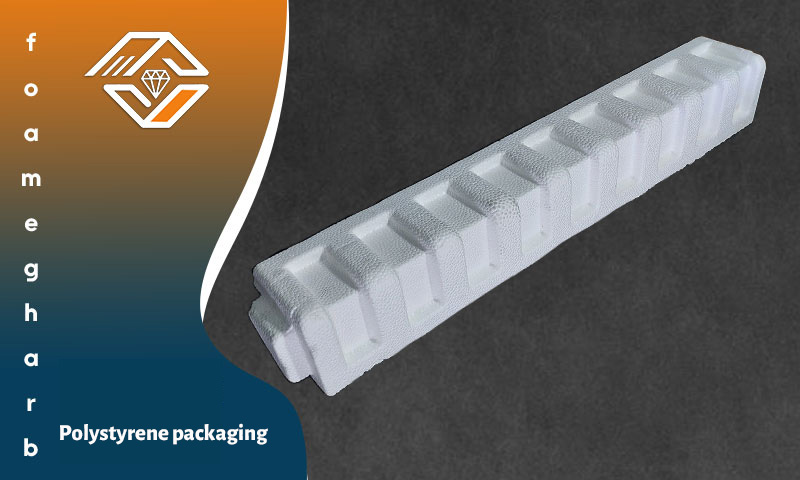

a.Pre-Made EPS

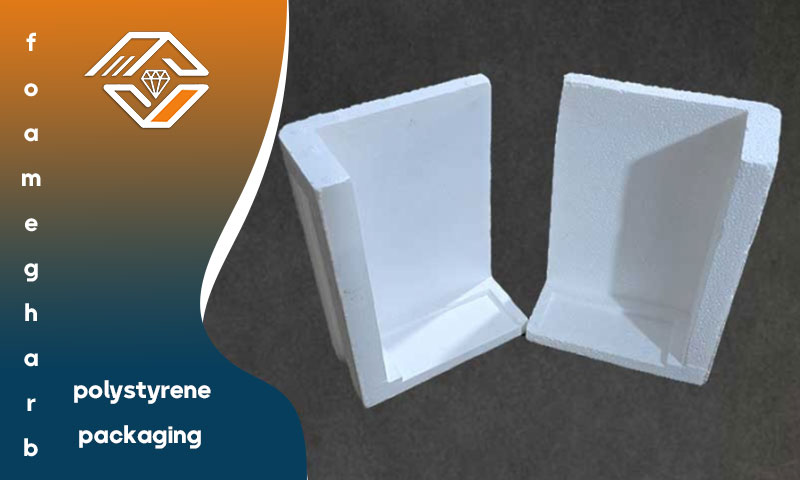

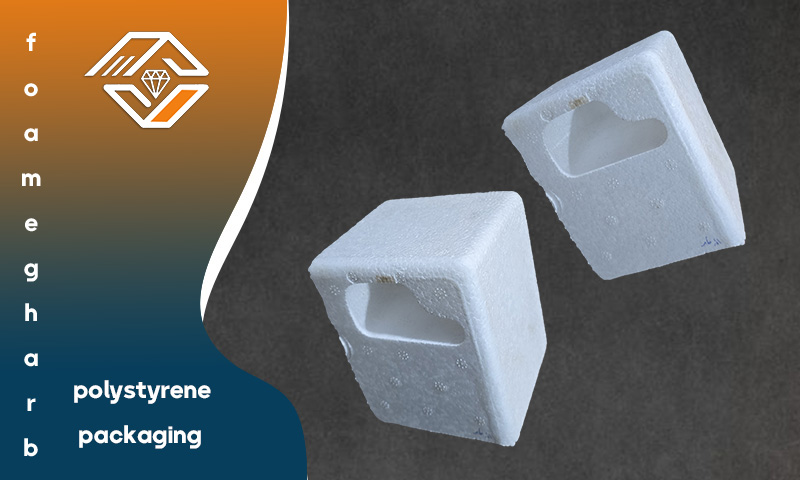

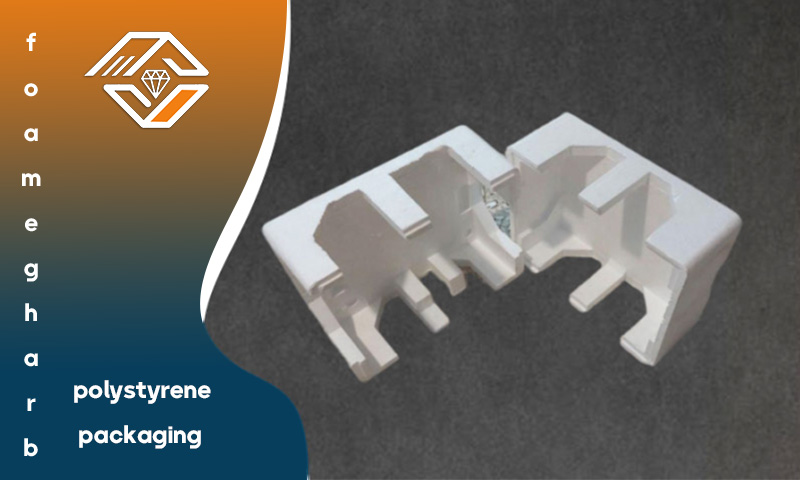

Pre-made EPS is available on the market in sheet form, shock-absorbing blocks, corner protectors, boxes, and more—produced in standard shapes and dimensions.

This type of EPS is ideal for general applications such as packaging home appliances, furniture, and similar products.

b.Custom EPS

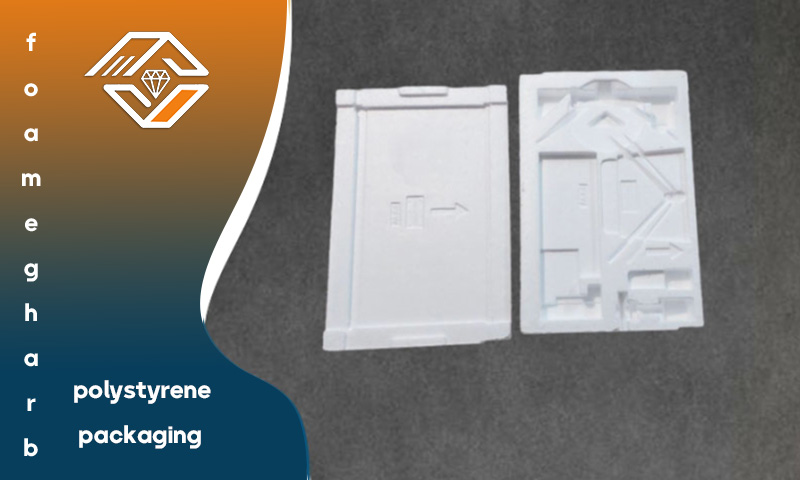

Custom EPS is produced based on the customer’s needs and exact specifications. For example, Polystyrene packaging for refrigerators, televisions, and industrial components falls under this category.

Types of Polystyrene packaging Based on Density

a.Low-Density EPS

This type of EPS is very lightweight and more fragile, making it suitable for products that have low weight and do not require high-impact resistance.

One of the main characteristics of low-density EPS is its extremely low weight. This feature makes it an ideal packaging material for lightweight and delicate items.

b.Medium-Density EPS

This type of EPS is used for general applications and is suitable for packaging a wide range of products.

Medium-density EPS offers higher resistance to pressure and impact compared to low-density EPS. This makes it suitable for packaging products that require greater protection, such as sensitive electronic components or industrial items.

c.High-Density EPS

This type of EPS is very strong and relatively heavier, making it ideal for packaging products that require maximum protection against impact and compression.

High-density EPS, due to its higher material concentration per unit volume, offers superior strength and enhanced resistance to impact, pressure, and tension.

Because of its denser structure, it also provides better thermal and acoustic insulation—making it ideal for applications that require energy efficiency or noise reduction.

It is commonly used in the construction of insulated walls, prefabricated roofs, and building panels.

Properties of EPS in Packaging

Polystyrene foam, commonly known as EPS, is widely used in packaging due to its key features such as lightweight structure, insulation capability, and excellent shock absorption. This material protects products against physical damage such as impact and pressure, while also offering resistance to temperature fluctuations and moisture. As an affordable and lightweight packaging material, EPS helps reduce transportation and storage costs.

High-quality Polystyrene packaging is produced by Iranian West Foam Development Company, a manufacturer with years of experience and expertise in polystyrene (EPS) production. The company offers a wide variety of EPS products tailored to customer needs, making it a reliable choice for those seeking safe and cost-effective packaging solutions.

For purchasing or obtaining more information, you can contact the phone numbers provided on the website and order high-quality, reasonably priced Polystyrene packaging products.

Features and Applications of Polystyrene packaging

As mentioned above, polystyrene (EPS) offers numerous advantages, making it a widely used material across different industries. Some of the most notable features of EPS include moisture resistance, thermal and acoustic insulation, lightweight structure, cost-effectiveness, long service life, easy handling and transportation, and its environmentally safe characteristics.

Because Polystyrene packaging provides excellent resistance against moisture, temperature fluctuations, pressure, impact, and shock, it is suitable for transporting even the most delicate and sensitive products.

Today, Polystyrene packaging for home appliances is designed and manufactured in fully customized forms, ensuring that these items can be transported safely—even over long international distances—without damage.

Depending on the shape and dimensions of each product, a custom EPS mold or packaging box is designed and produced. For example, customized Polystyrene packaging is created for juicers, tea makers, kitchen sinks, and various EPS corner protectors.

Major Applications of Polystyrene packaging

-

Packaging fresh fruits

-

Insulation for evaporative coolers

-

Packaging large home appliances

-

Packaging automotive spare parts

-

Packaging various industrial components

-

Packaging electronic components

-

Packaging household items

-

Packaging sanitary products and faucets

-

Packaging pharmaceutical products

-

Creating decorative structures

-

Packaging fragile and breakable items

Why EPS is the Best Choice for Packaging Sensitive Products

Packaging sensitive products that are prone to impact and damage is one of the major challenges across various industries. Polystyrene (EPS) is recognized as an ideal material for this purpose. Thanks to its unique properties, EPS can effectively absorb external shocks and pressure, making it an excellent option for packaging easily damaged items such as electronics, glassware, or sensitive pharmaceuticals. EPS helps prevent product damage during transportation and storage.

With features such as lightweight structure, superior shock absorption, moisture resistance, and full customizability, Polystyrene packaging is one of the best choices for protecting sensitive products. In addition to preventing damage, Polystyrene packaging reduces costs while ensuring greater safety and protection during transit. For these reasons, packaging EPS has become an essential component in the packaging process across many industries.

Manufacturing Molds for Polystyrene packaging

Iranian West Foam Development Company has established an in-house mold manufacturing unit for EPS to enhance production speed, ease of work, and product quality.

As we know, proper packaging is crucial for manufactured products. Efficient packaging ensures safe stacking, storage, and transportation, ultimately delivering the product intact to the end consumer.

Polystyrene packaging acts as a reliable shock absorber to protect the final product. To ensure optimal protection, the EPS must match the shape and dimensions of the item. Therefore, producing packaging EPS for each product requires a specially designed mold.

Environmental Benefits of EPS

-

Recyclability: EPS can be recycled to produce new products. This not only has economic and environmental importance but also helps reduce waste and conserve natural resources.

-

Reduced Raw Material Consumption: EPS is a lightweight material, so it requires fewer raw materials compared to alternatives like wood or plastic. This contributes to preserving natural resources and reducing greenhouse gas emissions.

-

Insulation Capability: EPS provides excellent thermal insulation, helping maintain heat and cold within buildings. As a result, it reduces energy consumption and lowers greenhouse gas emissions.

Ordering Cold Polystyrene packaging

Cold Polystyrene packaging, also known as expanded polystyrene (EPS), is a lightweight yet rigid foam material commonly used for packaging and insulation. Key features of cold packaging foam include:

-

Made from polystyrene resin that expands into a cellular structure, creating a material that is both lightweight and durable.

-

Offers excellent thermal insulation, making it ideal for packaging perishable items such as food, pharmaceuticals, and electronics.

-

Water-resistant and shock-absorbing, with the ability to be molded into custom shapes for specific products.

-

Commonly used for cooling devices, protective packaging for fragile goods, and insulation for buildings and home appliances.

-

The cellular structure gives cold foam low density and strong insulating properties while maintaining durability and strength.

Cold packaging foam is an affordable, versatile packaging solution with wide-ranging applications.

Polystyrene packaging for Home Appliances

EPS is one of the best polymers available for use as a shock absorber and is widely used in the packaging industry for electronics and home appliances.

Polystyrene packaging serves various purposes, with the most important being the safe packaging of all home appliances and other products.

Here are the main features of EPS packaging for home appliances:

-

High resistance to impact, pressure, cold, heat, and moisture

-

Ability to compress products for secure packaging

-

Extremely lightweight, adding no significant weight to the product

-

Recyclable material

-

Easy to cut and shape

-

Available in various sizes and custom designs

-

Protects products from all potential damage, including breakage and spoilage